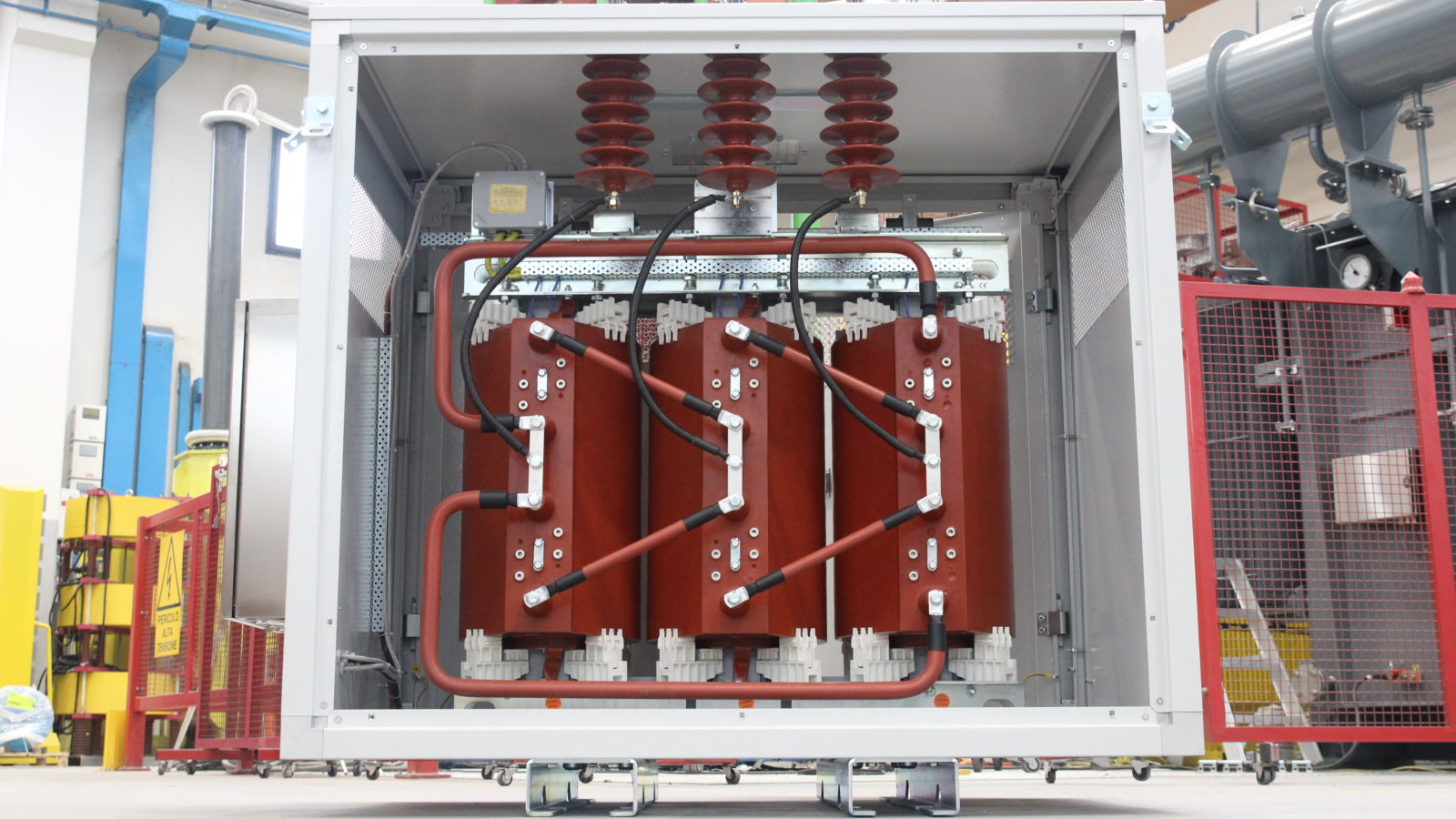

Cast resin and dry type transformers

EBG manufactures air insulated and encapsulated transformers for distribution and special transformers from 50 kVA up to 10,000 kVA for all voltage classes up to 52kV (BIL 250). All production is internal, from the carpentry for pressing of the core up to the assembly of the transformer complete with box according to the desired IP, and final testing.

The carpentry is separated from the other production areas to avoid contamination problems. It is equipped with automatic laser cutting with automated sheet storage, press-bending machines with 5-axis control, 8 welding stations, a sandblasting cabin for the treatment of the sheet metal and therefore a state-of-the-art painting system with washing, phosphorus greasing, drying and flow-coating and airless system based on the desired class from C3 for indoor installation up to C5X for offshore applications.

The machines for making the windings are newly built and remotely controlled, therefore synonymous with precision, quality and speed.

The primary and secondary windings of the transformers are made of aluminium or electrolytic copper with enamelled insulation or are Nomex coated according to the size of the conductor and the insulation voltage. The insulation between coils and layers is made with polyester (class B = 120°), DMD (class F = 155°) or Nomex (class H = 180° and class N = 200°) based on the thermal class to be guaranteed on the transformer. The winding can be made of slab, wing nuts, for vertical fall or disk according to the currents involved and the losses to be guaranteed on the windings. For higher currents, windings are made with transposed cable or other specifically designed technical solutions. In resin transformers the medium voltage windings are filled with epoxy in an autoclave and the low voltage windings are impregnated under vacuum with class H polyester resin.

The assembly is carried out in 16 independent workstations that allow the industrial production of transformers, allowing the product to be competitive and of the highest quality.

All the production of resin transformers takes place in class E2, C2 and F1 but we can also guarantee class E3 (wind installation) and C4 (installation at low temperatures down to -60°C).